Keyboards are important. Just about everything is wrong with the keyboard below. (The original sharps are beautiful.)

Plastic key tops can also be damaged or come unglued if contact cement is used as an adhesive.

The picture below shows a key top as it is removed on the band saw. A precision jig that runs on a track is required to do this.

All the ivory used is legal ivory with papers provided to you certifying origin.

It is important that the ivory have an East African origin as it is superior in texture and color.

(Note: If the ivory is not used on a piano keyboard it will be carved up for some other purpose. We feel the

utility as ivory keys to be far more useful than carving it into a sailing ship!)

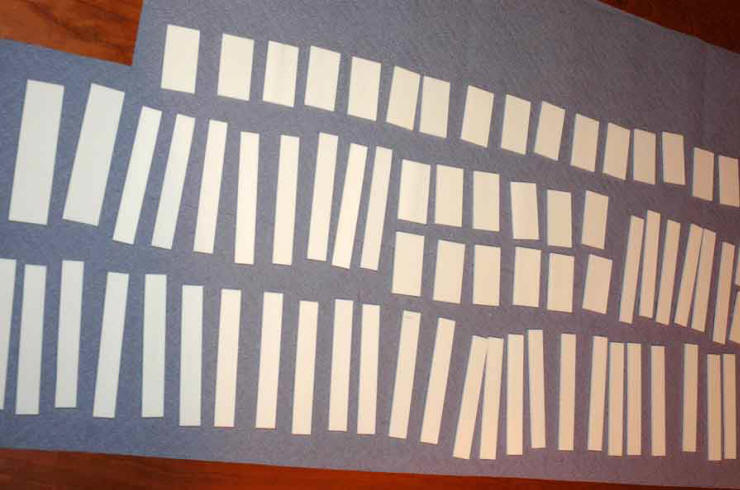

Ivory laid out for drying:

The new ivory is book-matched, the grain of the ivory matched.

Lights out!

The keys and key frame are so dirty that they must be improved by bead blasting and finish sanding.

If the keys were sanded down improperly new wood must be added to the sides of the keys to build them up to original specifications. Otherwise you have large gaps between the keys.

Then the new ivory is installed using a special glue.

Ivory toothpicks.

There are many stages of shaping the ivory down to 2000 grit and polishing. The work is very labor intensive. While this picture shows only one key initially sanded, two at a time is the general rule in order to keep the ivory level.

Marking out of the notch for the sharp and filing to achieve an identical match from key to key.

After the many sanding and polishing procedures the ivory is translucent and gleams . Wouldn't you really rather be playing on an ivory and genuine ebony keyboard? The value of your instrument would be vastly increased and the basis of your investment, a long term one.